An interesting discovery by UNH professor Xiaowei Teng could lead to a better, safer battery – something the world really needs – but before we get to the details, check out a comment he made about the lab’s multi-year effort:

“We found the material with this unique performance in the first year. The rest of the two years was finding why this material, and why not others,” Teng said in a phone interview. “You get excited when you (find something), but you want to understand why. Then, you can apply this principle to design even more efficient materials.”

In other words, his lab looked for something – in this case, a material for electrodes that could store more energy in a battery using water as an electrolyte – and they found it. But instead of declaring victory, that’s when they really started working.

Why? Science!

In science, it’s not enough to dream up a cool theory and talk about it: That’s philosophy. And it’s not enough to find something that works and keep doing it: That’s folk knowledge. It takes both practical and theoretical, endlessly feeding off each other, to create science.

The hypothesis shapes the experiments you run, and their results reshape the hypothesis, and that shapes more experiments, and so on until you’ve got something solid enough to be shared. It might even become a scientific theory that could change the world – until it gets supplemented by work from another scientist, of course.

The finding by Teng and his two Ph.D. students may not change the world, but it shows promise in a technology where promise is needed: Energy storage in batteries.

A battery is a method of storing electrical energy as chemical energy. This usually involves placing two different metals (the electrodes) in a substance called an electrolyte, usually a liquid, so that electrons move between the metals when desired. The chemical interaction among the metals and the liquid create characteristics like voltage, life span and ability to be recharged.

The lead-acid batteries in our cars use – can you guess? – lead and dilute sulfuric acid, which is why they’re so nasty. Nickel-cadmium batteries use those two metals and various electrolytes, while lithium-ion batteries use lithium and an electrolyte that can be solid or liquid. Lots of other battery types also exist, with differing performance or cost attributes.

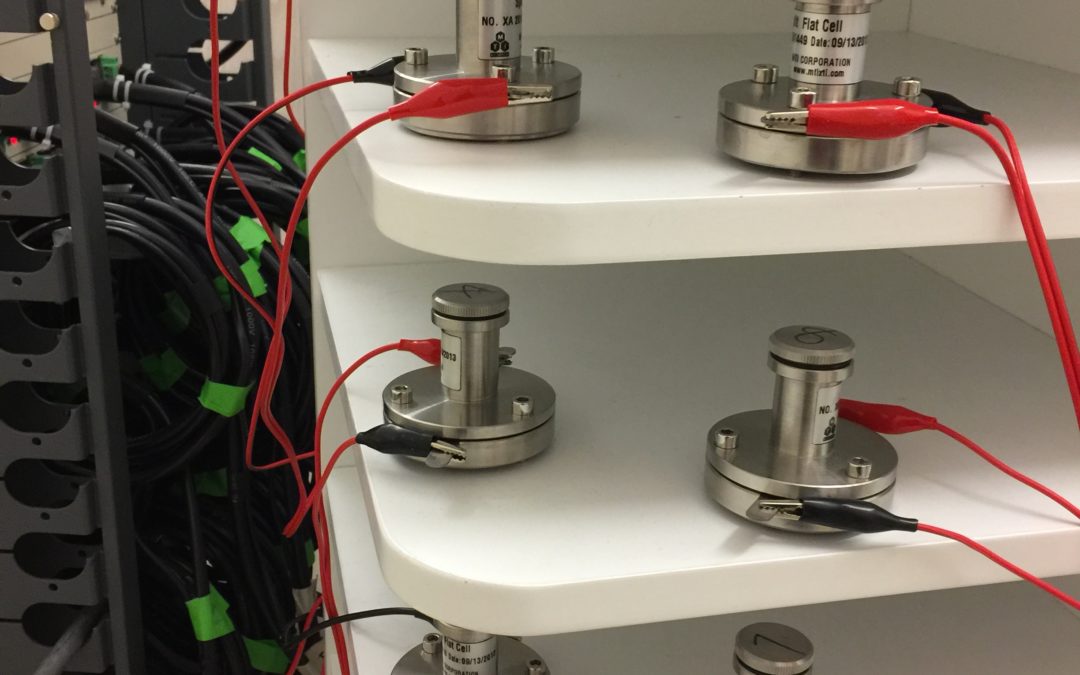

Teng’s team studied batteries that use water as an electrolyte, known as aqueous batteries. Water is safer than any other electrolyte, not to mention cheaper and easier to manufacture, but it doesn’t work very well with known electrodes.

They worked with manganese oxide, a known electrode for aqueous batteries that doesn’t have enough oomph (1.2 V rather than 3.5 V as needed) because it reacts with water at higher voltages and loses its effectiveness.

“From the first, we targeted this limitation . . . and modified the material, so it is much more inert to the water decomposition,” Teng said.

Specifically, to use phrases I’ve swiped from the abstract of their paper published in Nature Communications, they layered the alloy with “a well-ordered hydroxylated interphase” which “suppresses the gas evolution reactions, offers a two-electron charge transfer via Mn2+/Mn4+ redox couple, and provides facile pathway for Na-ion transport via intra-/inter-layer defects of (magnesium oxide)” and thus “demonstrates a stable potential window of 3.0 V in an aqueous electrolyte, as well as high energy and power performance, nearly 100 percent coulombic efficiency and 85 percent energy efficiency after 25,000 charge-discharge cycles.”

Yeah, I’m a little foggy on the details, too. Chemistry isn’t my strong point.

But there seems to be an understanding of what’s happening in a way that Teng or others can use and improve upon, perhaps creating aqueous batteries that can leave the lab and enter the commercial world, which is a tough jump to make.

Importantly, Teng didn’t present the finding as a “this-changes-everything!” story. He said that water has unique weakness as an electrolyte, which means he doesn’t think it will reach the high-energy density needed to, say, supplant lithium-ion batteries.

But it doesn’t have to in order to be important.

“There will never be one operational system to dominate this market,” he said. “It depends on the needs of the customer.”

For example, batteries to provide home energy storage, as in Tesla’s Powerwall, can be relatively big and bulky.

“For home storage, you probably don’t really care about size – you care about safety first, second is cost” and third is whether it can operate effectively for a long time.

Cellphone batteries certainly do care about size, however, but perhaps not life. “Do you really need a cellphone battery to run over 10 years? I don’t think so – two years is probably enough because you’re going to replace it anyway,” he said.

So a battery technology that works for one system may not work for another. As the industrial world becomes increasingly electrified, full of utility-scale battery storage, long-distance electric trucks, electric airplanes and LED clothing (honest), we’ll need energy storage systems with a variety of characteristics.

Teng, who has worked in electrochemical research since he was a student, said Durham is “a good environment, they know the importance of research” as well as teaching. He continues to work on the system with Xiaoqiang Shan and Daniel Scott Charles, Ph.D. candidates in the chemical engineering department at UNH, under a U.S. Department of Energy grant.

He admits that while it’s fun to make interesting scientific discoveries, it’s more fun when they have a chance of showing up in the world some day.

“It’s transformative; you feel very excited, ” he said. “A good result moves outside the lab, in the real world.”

Return to the Concord Monitor

Return to the Concord Monitor