It is becoming increasingly clear that electric vehicles are the future of vehicles. But who’s going to fix them when they break down?

The world’s greatest grease monkey (as a mechanical dunderhead I use that term with respect and admiration) can’t do much if your electric car’s battery management system fails. That’s a concern which is starting to resonate with industry, including the folks in New Hampshire who train tomorrow’s auto mechanics.

“Tesla reached out to us,” said Marc Bellerose, chair of the automotive technology department at Manchester Community College. “They were looking, just like everyone else, to bring new technicians into their industry.”

Last week, this question brought 22 teachers from high school auto-tech programs around the state to Nashua Community College, one of several state community colleges that train auto technicians (Concord’s NHTI is not one of them).

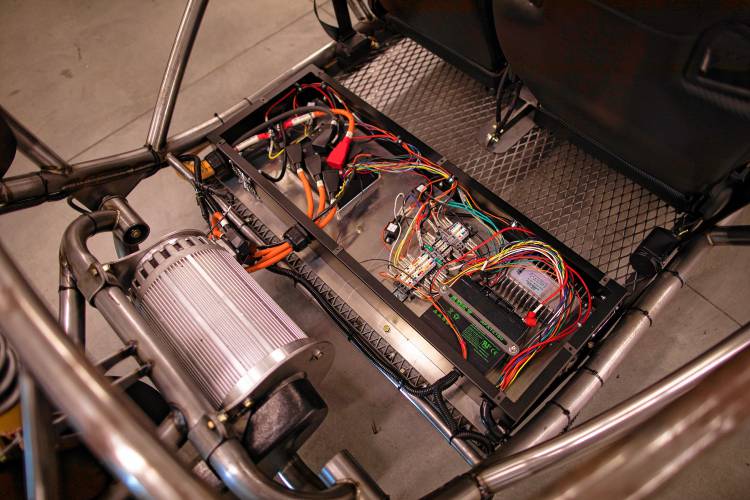

As part of continuing education to keep their certification, the teachers had classroom work; checked out a Mustang Mach-E, Ford’s first entry into the battery-electric market; looked at the stripped-down Switch Lab electric vehicle used for training; and talked about life once engine oil changes are a thing of the past.

“For five years out, maybe 10, I don’t see it changing,” said Scott Mayotte, who teaches auto technology at the Concord Regional Tech Center at Concord High School.

That’s partly because the introductory classes of tech training have to spend their time on the basics starting with “righty-tighty, lefty-loosey,” and partly because they have to teach about current systems that will remain no matter what, such as suspension, brakes, lights and steering. Also, every internal-combustion vehicle sold today is going to need a mechanic for its working life; our roads won’t be EV-only for decades.

But the biggest problem may be that it takes specialized equipment and training to work on electric-car batteries as compared to traditional low-voltage auto electronics.

“There’s even special gloves, fencing. … I don’t see high schools having the equipment, the training,” said Mayotte. “Not for a long time.”

All auto-tech classes already teach safety around high-voltage electronics because of hybrid cars, but those classes don’t go much beyond telling students what not to touch. The Switch Lab training car, which is used in some high school courses, is more hands-on but has a specialized battery design that keeps it below 60 volts.

The immediate future might be different at the next step up, the community college level. They offer one-year certificates and two-year associate’s degrees as an auto mechanic, although it takes certification from manufacturers to work on some systems. “You’re a lifelong learner,” Mayotte said.

Nashua Community College is in the process of assessing how it should alter curriculum and courses to train electric-vehicle mechanics, which also involves how to integrate this future technology into all their other departments.

“We want their log files for database analysis,” said Prof. Betsy Gamrat, who coordinates Computer Science and Web Engineering & Computing Sciences at NCC, gesturing at an electric car.

Cars are an interesting challenge for wannabe software developers, she said, because failure can be life-threatening.

“The quality of software you need in a car has to be extremely high. That’s part of what we teach: the use that software is put, that determines where you should draw that line,” she said.

“Look at that battery management system,” Gamat added. “There’s no keyboard, no screen; it’s a whole different ballgame.”

Part of the issue of electrification of motors is that it will speed up the pace at which cars become mobile computers. As the recent computer chip shortage has shown, even gas guzzlers depend on dozens of modules, each basically a small computer, to control everything from engine operation to pollution control to audio systems. Auto mechanics won’t have to be programmers but they will need skills more often found in the I.T. department.

“The students are not writing code, but they do reprogram the computers on the car,” said Bellerose. “If you replace a transmission, you have to go to the programming procedures for its computers – they have to be set back to zero, if you will, so it knows that this is a new transmission. … You’re a software user and an installer.”

Electric mobility is going to redefine cars and trucks in ways that haven’t happened such at least the invention of the automatic transmission or the electric starter, to the point that transportation won’t be the only thing mechanics have to think about. Dealing with vehicle-to-grid technology, in which a car or truck system can power a house, is going to become part of the auto technician’s toolbox.

“These are not just a vehicle that gets from point A to point B,” said Prof. Karl Wunderlich, chair of Industry and Transportation Department at Nashua Community College. “The mindset of students is starting to open to that idea.”

This is not, of course, the first time the auto industry has adjusted training due to technology. Ask starting mechanics about carburetors and you’ll probably get a blank look.

“The job hasn’t shrunk – if anything it has just expanded,” said Bellerose. “You need to know all the fundamental things you would do as a technician, and then you add more technology. … It just keeps growing.”

Return to the Concord Monitor

Return to the Concord Monitor

How and where will these batteries be disposed of?

Plenty of places; it’s easy to find online. Other questions to consider: How and where are the batteries in the millions of cars on the road disposed of? How and where are all the other pollutants associated with gas-burning cars disposed of?

Good point – we need people who will fix EVs. As one who has owned a hybrid, I found it hard enough to get that system fixed! At the rate Detroit and others are plunging into EVs, another uncertainty besides available technicians much ignored in all the enthusiasm is the electrical infrastructure necessary to support a massive vehicle transition from fossils to electrics. It should be at least somewhat economically comparable to the end user as the fossil alternative. Just now, the situation is not promising. We are dealing with a system problem. And the situation must answer to economic and political constraints. The transition cannot be an uphill fight, but right now, only $65 billion is allocated from electric infrastructure improvements, much of it just to improve and repair existing facilities – it is hard to find how much more power at lower rates is planned to be generated. Otherwise, EVs will remain as they are now, a niche – and companies ramping them up at present may be sorely disappointed, unless electricity is quite a bit cheaper everywhere than it is now. And if the infrastructure (both generation and distribution, plus fast charging stations) supply doesn’t keep up with EV demand, electricity prices will rise for all uses, not just for those driving EVs.

I know that Duncan’s European Automotive in Londonderry services Tesla.

They have a fast charger outside.

They also have the tools and software to service EV’s.

I can see how finding the right technicians is going to cause some serious problems for EV owners (if it hasn’t already). To make matters worse, I’ve heard that after driving an EV for five or six years, the battery must be replaced; the price for replacing an EV battery is in the range of four to six thousand dollars.

Another problem is that the US is trying to phase out coal, although coal is still the predominant fuel for generating electricity in this country. Solar and wind generate only about 10% of all the electricity used in the US. How are all the fossil fuel cars going to be replaced by EVs considering that they rely on coal to generate the electricity to recharge?

I doubt that EVs will ever completely replace conventional fossil fuel cars. Good luck!

You have heard wrong – EV batteries are lasting *many* years longer than that. Check it out online!

As for the grid, there’s plenty of discussion about how it will adjust to EV’s. That’s not a deal-breaker: Europe and China already have EV adoption 5X or 10X of the U.S.

It is good to know that technology improves over time.

Thank you.

Power companies are going to natural gas and nucular energy

Looking for training opportunity for upgrade of skills to handle EV, for someone who is currently into auto diagnostics and veh repairs.