NOTE: Her talk is Thursday, July 9.

Nancy-Lee Rodden was given an unexpected task after she got an accounting degree in college and started working.

“One of my first jobs was to figure out how much it cost to build a space suit,” said Rodden, a native of Nashua. The firm, ILC Dover in Delaware, a maker of materials designed to withstand extreme environments, wanted to bid on a NASA contract for new space suits during the Apollo era. “I had to look in materials, hours of construction, all that. And it made me interested in how it was put together.”

That interest has lasted decades, turning Rodden into a traveling ambassador for space suits. She’ll be giving a talk about their design and construction at the Aviation Museum of New Hampshire, at the Manchester-Boston Regional Airport, on Thursday at 7 p.m. It’s free for members, $10 for others; details at aviationmuseumofnh.org

The key point in her talks: Space suits aren’t what you and I think of as a “suit.”

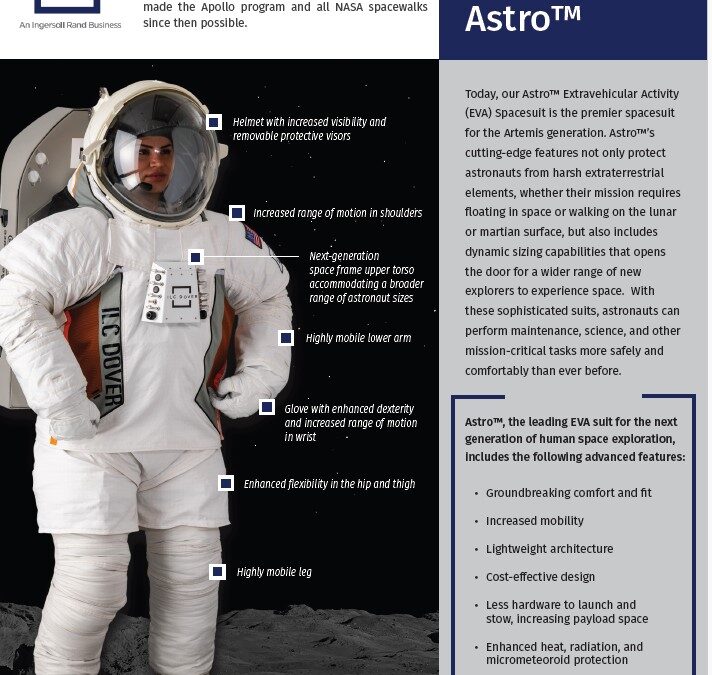

“A space suit is a personal spacecraft. It has to do everything that the [International Space Station] does for the astronaut: life support, air conditioning or heating and protection from the environment around them.”

The job might be similar but the construction is very different. “A space suit is made on a sewing machine. It is fabric… with metal parts.”

The metal bits — connecting rings, the helmet, and so on — are made by Air-Lock in Milford, Connecticut; ILC Dover makes all the fabric coverings and portions.

That turns out to be something of a problem from the perspective of a labor force, Rodden said.

“Sewing has become a lost art. The past few years we’ve lost a lot of talent through retirement, and it has been very hard to find trained sewers. A lot of newer talent is coming out of fashion design,” she said. “Engineers on the floor have fashion degrees.”

Maybe “Project Runway” should have a season in which contestants submit competing designs for 300-pound enclosed suits that keep you from dying of CO2 overload while breathing hard for hours at a time.

300 pounds — really?

“Oh yes. You don’t walk in a space suit” Rodden said.

Space suits are tested in swimming pools to simulate zero gravity, and just getting into them requires lifting the suits with a crane. On the space station, she said, the suits are attached to the wall in two pieces and astronauts basically climb into them and have others attach the components, with the helmet and gloves coming last.

“We do not build suits to fit one person, build it small, medium, large, of all the different parts. Right now we’re making a lot of smaller sizes for women. The trickier build are the gloves, which have to be flexible even as they keep out the vacuum of space. Those are built individually for each astronaut,” Rodden said.

In case you’re wondering, since everybody does, astronauts wear adult diapers for the spacesuit sessions, which last many hours.

Rodden will have a full-size replica of the suit at her talk. Not the whole thing of course: “If it weighed 300 pounds, I couldn’t take it around.”

Return to the Concord Monitor

Return to the Concord Monitor