I have written a couple times about Q Hydrogen, the Utah firm that bought a closed mill in Groveton and says they’re converting it to make hydrogen with a new technology. They’ve never been clear about what the technology involves, although patents show some hints, which makes it hard to know how seriously to take them. Here’s my Jan. 2020 story.

N.H. Business Review touched base with the CEO for a new story (story is here) but the company provided no more details than when I talked to them years ago. It’s “innovative” but exactly how is unclear.

Return to the Concord Monitor

Return to the Concord Monitor

Any idea which basic route they are going to take for getting H2?

The three routes I’m aware of are 1) electrolysis of water, usually at warm temperature, say 200 – 300C and with expensive precious metal electrodes (requires large amounts of cheap electricity); 2) thermochemical cycles, using heat to decompose one species, cooling the products of that down and reacting with water to pull off hydrogen (then cycling back again); 3) natural gas reforming, which needs natural gas input (this is the incumbent technology, which is hard to beat on price).

The thermochemical cycles use high temperature heat as an input. They’ve been proposed for example to use heat from nuclear, or concentrated solar thermal. Seem like great ideas but most of them involve very reactive chemicals like sulfuric acid which present containment & materials problems at the high temperatures, generally over 800C. I don’t believe anything like this has ever been scaled to commercial operation.

I’d guess it’s electrochemical but wonder if any hints point toward confirming that.

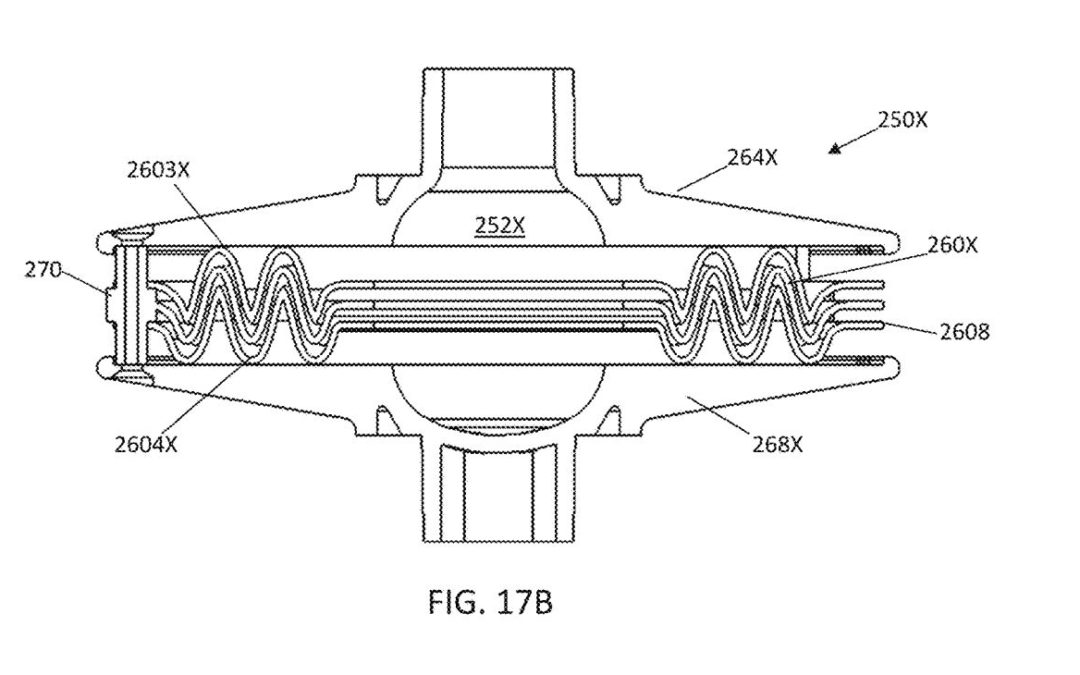

That attached patent – which may or may not be involved – is the only clue we’ve got. Until they talk about it!

its not the listed methods. its new. it uses schauberger based tech. the s bladed turbines and such. it creates sound waves and resembles sonolysis or the “water hammer effect”